The revolutionary Vernacare single-use system for managing human waste provides enhanced protection for patients, staff, and caregivers by eliminating the handling of potentially contaminated reusable containers through a hands free operation.

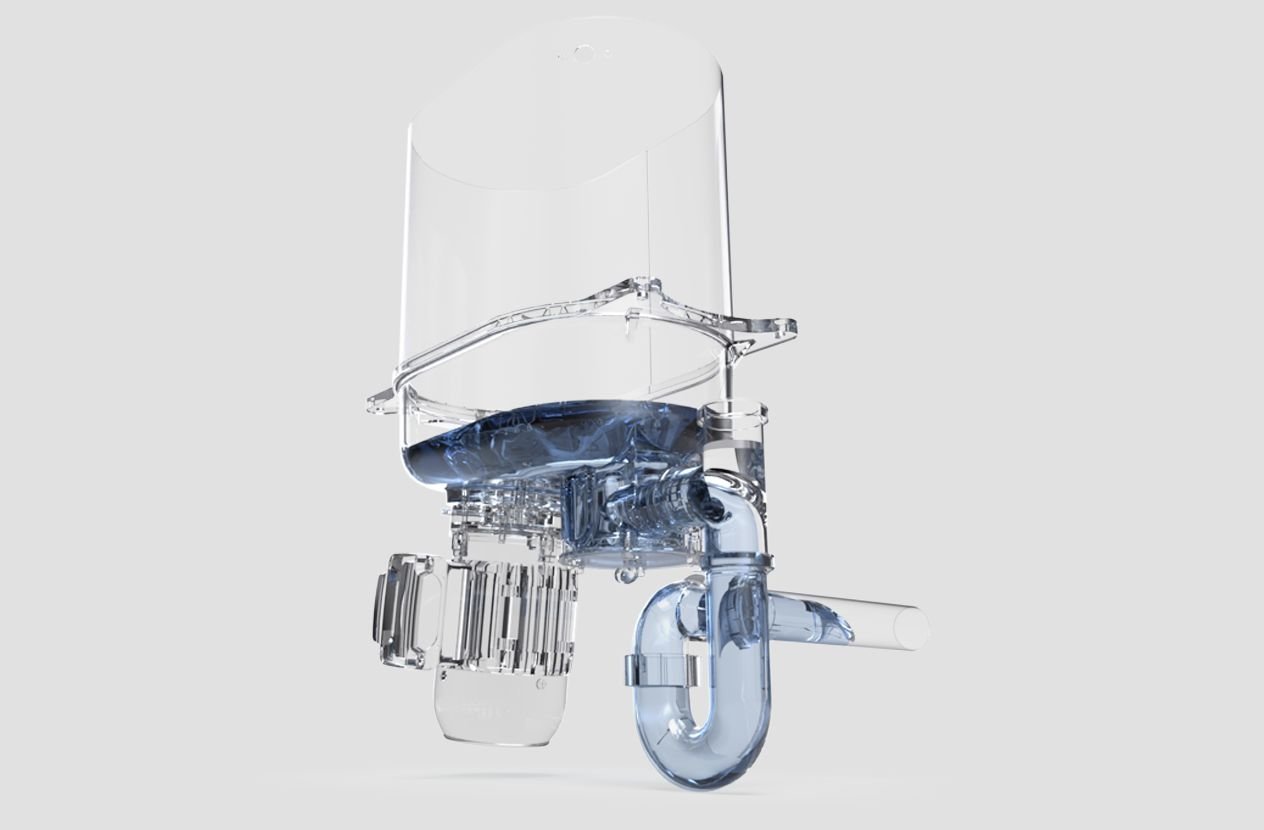

Vernacare's hospital macerators are designed to process single-use medical pulp products and human waste. The Vortex Air is the latest instalment in our range of hospital macerators, featuring the newest in macerator technology, offering superior diagnostics, sustainable design, and superior performance.

Why choose the Vortex Air?

Smarter Diagnostics

Something in your macerator that shouldn't be? The Vortex Air contains advanced diagnostics technology which protects against overloading which reduces machine downtime.

Sustainable Design

Did you know replacing your existing macerator with a Vortex Air can save over 20,000L of water per year?

Superior Performance

The Vortex Air utilises antimicrobial technology to further protect from HCAIs in the sluice room. It also has multiple cycle modes for optimisation in your sluice room, including quiet mode, heavy duty, and eco.

Key features and benefits

The Vortex Air utilises the latest in motor control and diagnostics tools to minimise downtime and improve performance.

Latest Technology

Inflatable Lid Seal

Smart Sensors

Digital Display

Water Efficient

Multiple Language Options

Multi-cycle to suit all healthcare facilities

Quiet Operation

Worker smarter to keep your teams safer

At Vernacare, we understand that machine downtime is not just disruptive, it can also pose an infection risk. We offer a range of serving solutions to ensure that your macerator always operates to the highest infection prevention standards. All of our engineers are accredited and trained to the highest standards, and with a number of Technical Services packages, we can keep your macerator running to its full potential.

Contact our Technical Team

Why choose a single-use disposable system?

The use of disposables was advocated by the World Health Organistion during the COVID-19 pandemic who stated that "equipment should be single-use and disposable to minimise the risk of transmission." Our system incorporates 100% biodegradable medical pulp products, disposed of into hospital macerators, with touchless and SmartFlow™ technology, and helps to eliminate healthcare-associated infections.

Eliminates cross-infection from risk of reusable bedpans

Hands-free system reduces number of potentially infected touchpoints

More convenient and hygienic

Immediate disposal reduces potential risk of contamination spray, splash backs, or spillages during cleaning

Zero aerosols released during disposal, eradicates risk of transmission via droplets

Vernacare macerators use significantly less water than bedpan washers, and the Vortex Air only requires cold water to process pulp, resulting in less energy consumption per product

What is SmartFlow Technology?

Vernacare invented SmartFlow™ technology to protect the environment and the healthcare facility. Our unique 'closed-drum' system ensures that all waste placed into our machines is fully broken down before being released into the wastewater system.

Upon discharge, when crushed and disintegrated by the macerator, the Vernacare pulp decomposes into particles, 95% of which are less than 1mm and are easily transported by the sewage pipes to the wastewater treatment plans (the same consistency as toilet paper). Studies have proven our discharge flow rate is 4x faster than any of our competitors.